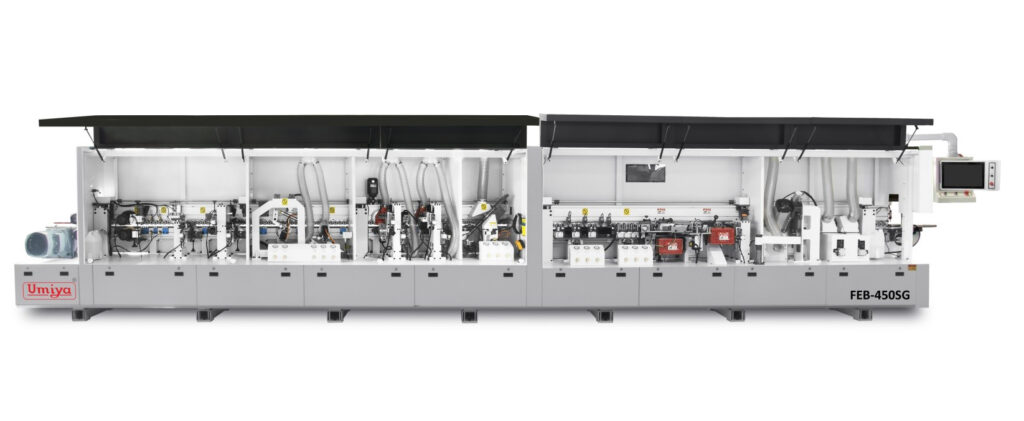

FEB 450SG

The Auto Edge Banding Machine FEB 450SG (STRAIGHT + BEVEL) is a high-precision, high-performance industrial solution crafted for modern furniture manufacturers who demand versatility and quality in a single machine. Combining straight edge and 45° bevel edge processing in one robust system, this machine transforms how panel edges are finished—delivering sleek, clean, and professional results for both standard and angled applications.

TECHNICAL SPECIFICATIONS:

| Description | Parameter |

|---|---|

| Edge Material Thickness | 0.4 – 1.5 mm |

| Board Thickness (Bevel Edge) | 15 – 25 mm |

| Board Thickness (Straight Edge) | 10 – 60 mm |

| Minimum Panel Length | ≥ 120 mm |

| Minimum Panel Width | ≥ 60 mm |

| Total Air Pressure | 6 Bar |

| Feeding Speed (Bevel Edge) | 13 m/min |

| Feeding Speed (Straight Edge) | 15 – 24 m/min |

| Electrical Lifting | 0.5 HP (0.37 KW) |

| Power | 36.5 HP (16.5 KW) |

| Packing Size | 10000 × 970 × 1800 mm |

| Control | PLC Touch Control |

Features

-

Dual-mode design for both straight and 45° bevel edge banding.

-

Supports edge thickness from 0.4 to 1.5 mm for versatile applications.

-

Handles board thickness up to 60 mm in straight and 25 mm in bevel mode.

-

High feeding speed: 13 m/min (bevel) and 15–24 m/min (straight).

-

User-friendly PLC Touch Control for easy and precise operation.

-

Powerful 36.5 HP system ensures stable, high-performance output.

BEVEL EDGE BANDING FUNCTION:

| S.No | Image Display | Function | Detailed Description |

|---|---|---|---|

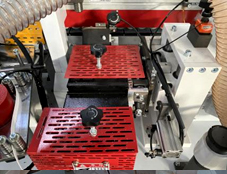

| 1 |  |

5.5KW BEVEL SAWING MOTOR | Straight board in and out, high power. Bevel edge saw pre-milled 45 degree edge, specially designed for bevel edges. |

| 2 |  |

BEVEL EDGE GLUEING POT (WITH SMALL STRAIGHT EDGE) | Glue pot and Bevel glue applicator shaft specially designed for bevel edges, front-mounted pre-heating lamp light, Preheat the board in cold weather to create a better bond between the edge band and the board. |

| 3 |  |

BEVEL EDGE TRIMMING | Designed according to the angle of the bevel plate, the upper flat knife and the lower tracking knife are used. Repair until the edge banding is close to the edge of the board . The cylinder moves forward and backward, switching freely. |

| 4 |  |

BEVEL EDGE SCRAPING | Designed for the characteristics of the bevel edge, the upper flat scraper and the lower R scraper are designed. |

| 5 |  |

EDGE BANDING WITH V GROOVE | Pre-milled V grooves for easy edge Banding and straight fold lines. |

| 6 |  |

BEVEL EDGE BUFFING | The buffing wheel quickly polishes the edge of the edge banding tape, and the two polishing. The light is sleeker and more beautiful. New series-action polishing, polishing motor pneumatic Moving in and out, the polishing wheel uses a larger area and the polishing effect is better. |

| 7 |  |

BEVEL EDGE BANDING EFFECT | Beautiful bevel edges, beautiful irregular bevel tracking arcs. |

STRAIGHT EDGE BANDING FUNCTION:

| S.No | Image Display | Function | Detailed Description |

|---|---|---|---|

| 1 |  |

STRAIGHT-SIDED EVA LOWER GLUE POT, WITH PREHEATING LAMP LIGHT | Straight board in and out, high power. Bevel edge saw pre-milled 45 degree edge, specially designed for bevel edges. |

| 2 |  |

STRAIGHT EDGE PRESSING WHEEL GLUING | After gluing, use the pressing wheel to make the edge banding close to the board surface. The pressing force can be adjusted. |

| 3 |  |

STRAIGHT EDGE TRIMMING | Six-edged alloy flat knife to trim excess edge banding tape. |

| 4 |  |

SCARPING STRAIGHT EDGE | The super carbide R knife smoothes the fine lines of the edge banding tape and makes it smooth. |

| 5 |  |

STRAIGHT EDGE BUFFING | The cloth wheel quickly polishes the edge of the edge banding tape. New series action polishing motor pneumatically moving in and out, the buffing wheel uses a larger area and the polishing effect is better. |

| 6 |  |

STRAIGHT EDGE BANDING EFFECT | The edge-Banding effect of the edge-banding tape is smooth and beautiful, with good wrapping properties and graceful bevels. |

SHARED FUNCTIONS FOR BEVEL EDGE AND STRAIGHT EDGE:

| S.No | Image Display | Function | Detailed Description |

|---|---|---|---|

| 1 |  |

SCREEN | 15-inch high-definition touch screen The industry’s leading touch screen in the woodworking industry , with fast response and no accidental touches |

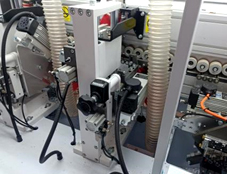

| 2 |  |

PRE -MILING | Diamond pre-milling cutter removes corrugation marks and excess from wood board spiral trimming cutter. The jointing unit is equipped with two high-frequency motors, which ensures high-quality processing of the end face of the material before gluing the edge. Pneumatically controlled pre-milling seat, more precise and easier to control. |

| 3 |  |

OBLIQUE STRAIGHT EDGE PRESSING WHEEL | Oblique straight cross pressing wheel specially designed for beveled edges. Can press bevel edges and small straight edges at the same time. |

| 4 |  |

END CUTTING | Cut off the excess edge banding at both ends of the board (with 2 pressure regulating valves and 1 pressure relief valve). The air pressure is more stable, and the pressure is more stable. |

| 5 |  |

CORNER ROUNDING | Trim the four corners after sealing into small arcs to make them smoother and less irritating. Tracking action and air path design designed with independent patented technology. Make the profiling chamfering action more stable |

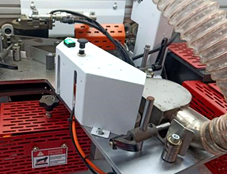

| 6 |  |

CENTRALIZED LUBRICATION SYSTEM | Automatic scheduled oil filling and maintenance, with multiple oil pipes connected to key moving parts. All-round lubrication reduces machine wear and extends machine service life. |

| 7 |  |

CLEANING DEVICE | Clean the remaining glue on the board and make it more beautiful. The nozzle can adjust the water volume. Front isolation fluid injection device and two sets of cleaning injection devices for the rear inclined plate and straight plate. |