Multi Blade Rip Saw For Flaw Piece

Multiple Blades: The saw is equipped with multiple circular blades that are spaced at intervals on the arbor. These blades are set at a fixed distance from one another, depending on the desired width of the finished boards.

Ripping Process: The lumber is fed through the saw where each blade cuts into the wood, producing multiple pieces simultaneously. The thickness of each piece is determined by the spacing between the blades.

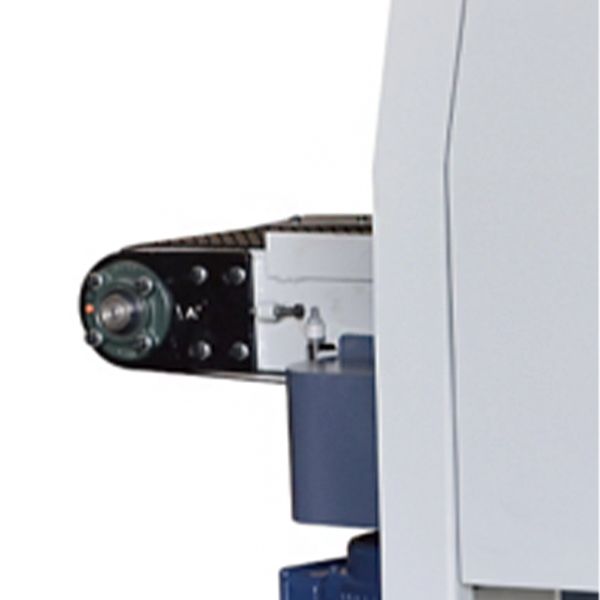

Feed Mechanism: The timber is typically fed into the saw either manually or through a mechanized feeding system. The speed at which the timber moves through the saw is crucial to achieving clean and accurate cuts.

Flaw Piece Handling: In the context of “flaw pieces,” the saw may be used to trim out defects or divide the wood into smaller sections that bypass or isolate imperfections. This can improve the yield from timber that has knots, cracks, or other defects that would make large boards unusable. By cutting around these flaws, valuable pieces of wood can still be obtained.

TECHNICAL SPECIFICATIONS:

Multi-Blade Rip Saw Specifications

| Description | UMBR-1330F | UMBR-1220F | UMBR-1315F | UMBR-1309F |

|---|---|---|---|---|

| Max Working Width | 300mm | 200mm | 150mm | 90mm |

| Max Working Thickness | 10-130mm | 10-130mm | 10-130mm | 10-130mm |

| Min Working Length | 850mm | 750mm | 750mm | 600mm |

| Feeding Speed | 0-32m/min | 0-32m/min | 0-32m/min | 0-32m/min |

| Motor Power | 40KW | 33KW | 33KW | 32.2KW |

| Machine Size | 3200x1460x1620mm | 3200x1460x1620mm | 3200x1240x1620mm | 2810x1180x1620mm |

| Blade Size | ⌀450x⌀50 | ⌀355x⌀50 | ⌀305x⌀50 | ⌀230x⌀50 |

Features

- Uniform Cuts: The saw produces uniform cuts with minimal variation in width, essential for downstream processes (such as planning or finishing). This accuracy is vital when working with timber that may have irregularities.

- Consistency in Board Quality: The multiple blades work in tandem to ensure that each piece is cut to the exact width required, maximizing the usable material and avoiding the flawed sections.

- Selective Cutting Around Flaws: Operators can adjust the blade spacing or alignment to avoid flaws like knots, cracks, or pitch pockets in the wood. This selective cutting ensures that the defective parts of the wood are bypassed, while the more valuable sections are processed.

- Wide Range of Applications: This saw can be used to process timber with different types of flaws, making it versatile in the sawmill industry for handling varied and imperfect wood.