Gang Saw

Stone Processing Industry: Gang saws are most commonly used in stone processing plants where large quantities of stone are cut into slabs for use in construction, landscaping, and decorative purposes.

Quarrying: Gang saws can also be used in quarries to process raw stone blocks into more manageable forms before further processing.

High Efficiency: Gang saws are capable of making multiple cuts simultaneously, greatly improving production speed compared to single-blade saws.

Consistency: The multiple blades help ensure uniform slab thickness across the entire stone block, which is crucial for large-scale projects.

TECHNICAL SPECIFICATIONS:

| Specification | UGS-3085 | UGS-30120 |

|---|---|---|

| Max Working Width | 300mm | 300mm |

| Working Thickness | 10-85mm | 10-120mm |

| Min Working Length (Single/Continuous) | 530/200mm | 600/300mm |

| Saw Spindle Dia | Ø 55mm | Ø 55mm |

| Reducer Sleeve Dia | Ø70mm | Ø70mm |

| Saw Spindle Speed | 4000RPM | 4000RPM |

| Blade Dia | Ø 205-Ø 305mm | Ø 205-Ø 380mm |

| Feed Speed | 4-30 m/min | 4-30 m/min |

| Total Power | 43.5HP | 53.5HP |

| Feed Motor | 3HP | 3HP |

| Spindle Motor | 40HP | 50HP |

| Lifting Motor | 0.5HP | 0.5HP |

| Dust Suction Dia | 2x Ø 150mm | 2x Ø 150mm |

| Overall Dimension | 1930x1580x1560mm | 2200x1500x1580mm |

Features

Vertical cutting: The blades are lowered into the stone block to slice through it, with the stone block remaining stationary.

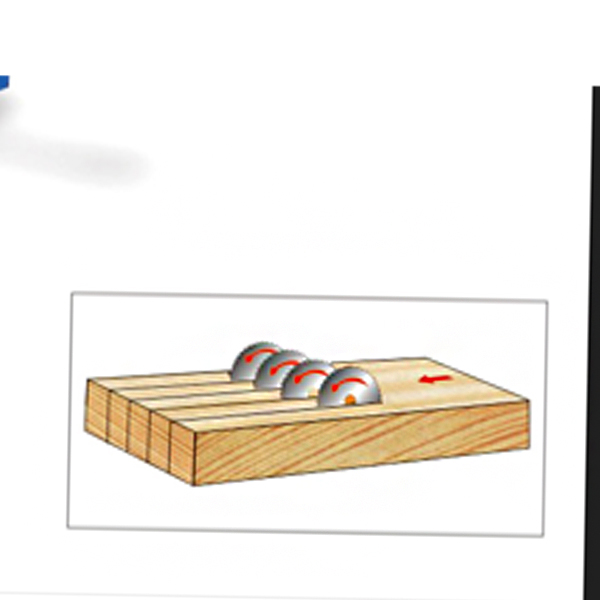

Horizontal cutting: The stone block is moved across the blades, which are stationary. This is often seen in larger, more automated systems.

Frame Gang Saw: This type uses a single frame to hold multiple blades in a vertical or horizontal position.

Diamond Gang Saw: Equipped with diamond-tipped blades, this version is designed for cutting harder stones like granite.

Multi-Blade Gang Saw: Features multiple blades in a series, allowing for faster cutting and higher productivity.