FEB - 460

The Auto Edge Banding Machine FEB 460 (HIGH SPEED) represents the next level in automatic edge banding technology, designed to meet the high-speed demands of modern wood processing units and furniture manufacturers. Built with innovation, efficiency, and productivity at its core, this advanced edge banding solution delivers outstanding performance, accuracy, and versatility in every run.

TECHNICAL SPECIFICATIONS:

| Description | Parameter |

|---|---|

| Edge Material Thickness | 0.4 – 3 mm |

| Board Thickness | 10 – 60 mm |

| Min Panel Length | ≧ 120 mm |

| Min Panel Width | ≧ 60 mm |

| Total Air Pressure | 6 Bar |

| Feeding Speed | 15 – 23 m/min |

| Electrical Lifting | 0.5 HP (0.37 KW) |

| Power | 16 HP (12 KW) |

| Packing Size | 5780 × 970 × 1800 mm |

| Control | PLC Touch Control |

| Dust Hood Size and Quantity | Ø 100 × 4 |

Features

-

High-speed feeding capability of 15–23 meters per minute for faster production.

-

Supports edge material thickness from 0.4 to 3 mm for versatile applications.

-

Handles board thicknesses from 10 to 60 mm with ease and precision.

-

Equipped with PLC Touch Control for smooth, intelligent operation.

-

Powerful 16 HP motor ensures consistent and reliable performance.

-

Features four 100 mm dust hoods for efficient dust extraction and cleanliness.

FEATURES:

| S.No | Image Display | Function | Detailed Description |

|---|---|---|---|

| 1 |  |

TOUCH SCREEN | 10-inch high-definition large screen The industry-leading touch screen “DELTA”, fast response, no accidental touches. . |

| 2 |  |

ANTI-PINCH DEVICE | If you accidentally touch the anti-pinch device during work, the whole machine will alarm and stop, it acts as a safety protection. |

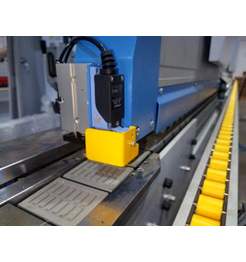

| 3 |  |

CONVEYOR ENCODER | The pulse encoder replaces the limit switch, and each function can be controlled more accurately. |

| 4 |  |

AIR PRESSURE PROTECTION DEVICE | When the air pressure is insufficient, the screen will display a low air pressure alarm and the machine cannot be started. It prevents damage to the board. |

| 5 |  |

PRE-HEATING PLATE | The pre-heating plate instantly heats the end face of board for better adhesion and solve the problem of cold areas in winter. Poor glue banding due to cold material. |

| 6 |  |

SIX ROLLERS OF PRESSING | One large, four medium and one silicon rubber coated pressing wheel with intergrated glue cleaning mechanism. 6 Roller of pressing and sticking are more precise than 4 Rollers, the glue line is slight and does not run away from the tape. Firm fit, thick and thin tape can easily go with the cylinder control. The pneumatic cylinder can control the glue door, the glue quantity is stable, and the thickness is even. The rollers are equipped with a glue cleaning mechanism. |

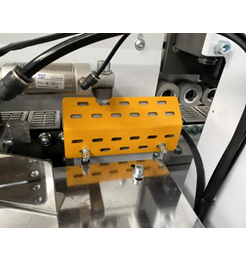

| 7 |  |

END CUTTING | Cuts off the excess edge banding at both ends of the flush plate (the cylinder is equipped with 2 pressure regulating valves and 1 pressure relief valve). The air pressure is more stable, and the pressure is more stable. |

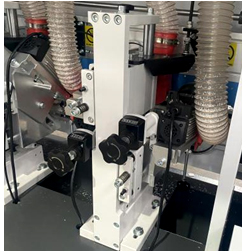

| 8 |  |

ROUGH TRIM | Adjust the knife using the digital meter, which is simple and easy to set. The six-edged alloy flat knife trims off the excess edges. |

| 9 |  |

FINE TRIM | The six-edged R knife trims off the excess banding top & Bottom tape to form rounded corners, trimming more beautiful. |

| 10 |  |

CORNER ROUNDING | Trimming the four corners after banding into small arcs is more rounded and less harsh. Self-designed tracking action and air circuit design make the profiling chamfering action more stable. |

| 11 |  |

SCRAPING | Super hard alloy R knife scrapes the fine lines of the edging strip to make it round and smooth. |

| 12 |  |

SPRAYING (CLEANING AGENT) | Cleans board residual glue, more beautiful, new universal joints. It has adjustable nozzle to control spray amount, easy to use. |

| 13 |  |

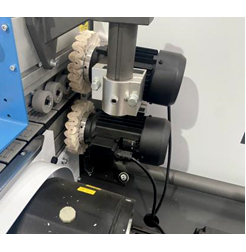

BUFFING UNIT | The cloth wheel quickly polishes the edges of and panel, excellent edge cleaning-polishing with two Independent motors. |

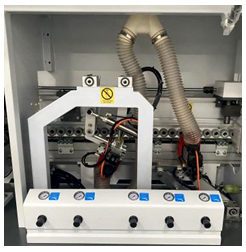

| 14 |  |

CENTRALIZED LUBRICATION SYSTEM | Automatic timed injection of oil maintenance, multi-lube connection to all trimming units moving parts. Preventive lubrication minimizes wear on the machine and increases its lifespan. |

| 15 |  |

NARROW BOARD AUXILIARY WHEELS | Installation of auxiliary leveling wheels at each functional point of force on the board’s forward route. It plays the role of flat support for narrow boards, so that the boards will not warp or fall off. |

| 16 |  |

CLAMPING MOVEMENT MECHANISM | The mechanism for lifting/lowering the clamping traverse is equipped with an electric drive, which ensures fast and accurate installation to the required thickness of the part. |

| 17 |  |

EDGE BANDING EFFECT | The edge banding effect of the edge banding strip is smooth and beautiful, with good wrapping properties and perfect chamfering. |