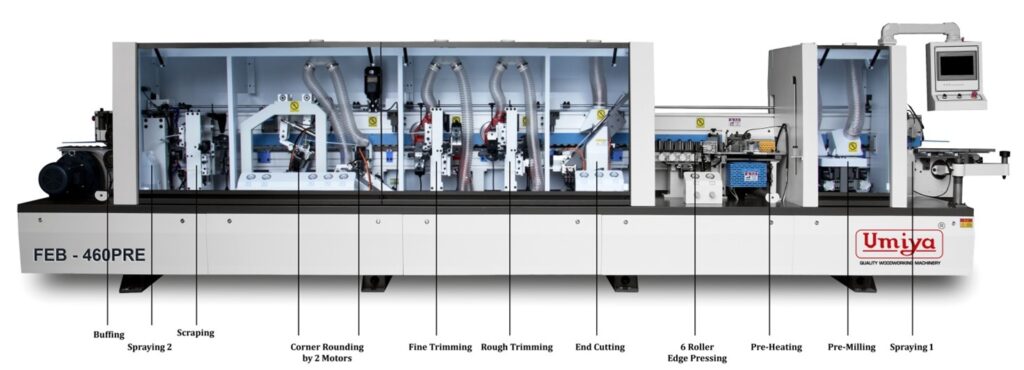

FEB -460PRE

- Main functions: Premilling–Gluing & Pasting—6 Wheel Pressing–Front And Back End Trimming–Rough Trim–Fine Trim–Corner Roun–Scraping–Spray Cleaning—Buffing.

- Scope of application: Suitable For Panel Furniture, Custom Furniture, Cabinet Wardrobe, Office Furniture, Solid Wood Furniture, Tables, Chairs, Doors And Windows, Wood Products, Decoration Industry, Etc.

- Processable Boards: Suitable For Various Boards Such As Density Boards, Ecological Boards, Multi-Layer Boards, Particle Boards, Straight Solid Wood Boards, And Aluminum Honeycomb Boards.

Technical Data

| Description | Parameter |

|---|---|

| Edge Material Thickness |

0.4-3 mm |

| Board Thickness |

10-60 mm |

| Min Panel Length |

≧ 120mm |

| Min Panel Width |

≧ 60mm |

| Total Air Pressure |

6 Bar |

| Feeding Speed |

15-23 m/min |

| Electrical Lifting |

0.5HP (0.37KW) |

| Power |

22HP (16.5KW) |

| Packing Size |

6800*970*1800mm |

| Control |

PLC Touch Control |

Features

- powerTouch operating concept as standard

- powerTouch operating concept as standard

- No setup required thanks to a vacuum-free clamping system

- Up to 13 vertical high-speed drill spindles including quick-change drill system

Products Details

| S.No | Image Display | Function | Detailed Description |

|---|---|---|---|

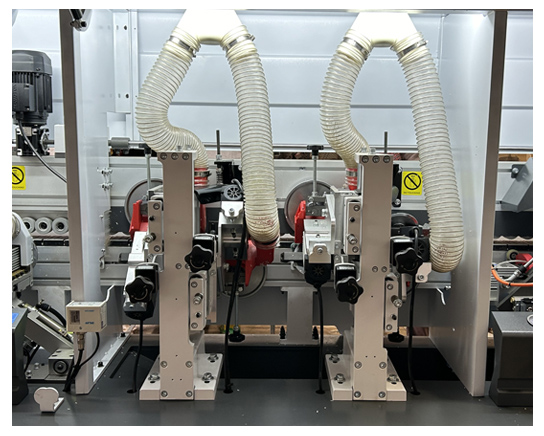

| 1 |  |

Touch Screen:10-inch high-definition large screen | The industry-leading touch screen in the woodworking industry, fast response, no accidental touch |

| 2 |  |

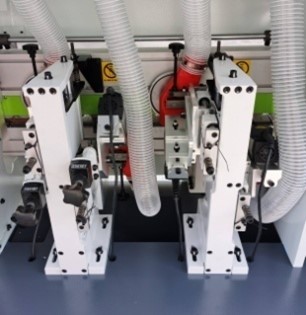

Pre-Milling | The diamond pre-milling cutter mills off the corrugated traces and redundant burrs of the spiral edge trimming knife of the wood board, so that the board edge fits the edge banding strip more firmly, and the bonding is more firm and more beautiful. Pneumatically controlled pre-milling seat is more precise and more convenient to operate. |

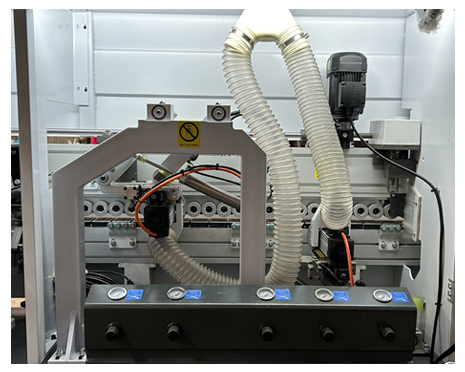

| 3 |  |

Front and back end cutting | Cut off the redundant edge bands at both ends of the plate (the cylinder has 2 pressure regulating valves and 1 pressure relief valve). The air pressure is more stable, and the head and tail are more stable |

| 4 |  |

Rough trim | It is easy to learn to adjust the knife with the digital table, and the six-edged alloy flat knife trims off the excess edge. |

| 5 |  |

Finishing Fine trim | The six-edged R knife trims off excess edge banding to form rounded corners, making the trimming more beautiful. |

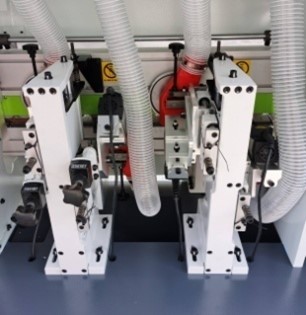

| 6 |  |

Corner Rounding | he four corners after the edge banding are trimmed into small arcs to make it smoother and less sticky. The self-designed tracking action and air path design make the profiling chamfering action more stable. |

| 7 |  |

Scraping | The superhard alloy R knife scrapes the fine lines of the edge banding to make it smooth. |

| 8 |  |

Polishing Buffing | The cloth wheel quickly polishes the edge of the edge banding, making it smoother and more beautiful. |

| 9 |  |

Centralized lubrication system | Automatic regular oil injection maintenance, multi-channel oil pipes are connected to all key moving parts, all-round lubrication, reducing machine wear and prolonging the service life of the machine. |

| 10 |  |

Cleaning Device (Optional) |

The superhard alloy R knife scrapes the fine lines of the edge banding to make it smooth. |